| PRODUCT | GRADE | EQUIVALENT STANDARD | CHEMICAL COMPOSITION (%) | SUPPLY CONDITION | APPLICATION | TYPE OF APPLICATION | ||||||||||

| AISI | DIN | JIS | Cu | Be | Zr | Fe | Ni | Mn | Zn | Pb | Oth. | |||||

| Brasses / Bronzes | ||||||||||||||||

| C22000 | CZ101, CW501L | CuZn10 | C2200 | 89.0-91.0 | – | – | 0.05 | – | – | 10.0 | 0.05 | Sn/0.05, Al/0.02 | – | Commercial bronze, 90/10 (Cu/Zn) have toughness, corrosion resistance, can be cold forming suitable for outdoor equipments |  |

| C26000 | CZ106, CW505L | CuZn30 | C2600 | 68.5-71.5 | – | – | 0.05 | – | – | 30.0 | 0.07 | – | – | Cartridge brass, 70/30 (Cu/Zn) has a springness, high toughness structure, resistant to weather-chemicals suitable for making fasteners, belts |  |

| C26800 | CW506L, CZ107 | CuZn33 | C2680 | 64.0-68.5 | – | – | 0.05 | 0.20 | – | 35.0 | 0.15 | Sn/0.05, Al/0.02 | – | Yellow brass, 65/35 (Cu/Zn), high toughness, spring structure, can be rolled, good machinability, corrosion resistant, suitable for making jigs and containers |  |

| C27200 | CZ108, CW508L | CuZn37 | C2720 | 62.0-64.0 | – | – | 0.05 | 0.20 | – | 37.0 | 0.05 | Sn/0.05, Al/0.02 | – | Cold forming brass, 63/37 (Cu/Zn), medium hardness, good electrical-heat conductivity, corrosion resistant except acetic, amonia, hydrochloric, nitric acids |  |

| C28000 | CZ109, CW509L | CuZn40 | C2800, (C2801) | 59.0-63.0 | – | – | 0.07 | – | – | 40.0 | 0.30 | – | – | Muntz metal, 60/40 (Cu/Zn), resistant to corrosion, can be hot formed well, commonly use in architecture, decoration design works |  |

| C36000 | CZ124, CW603N | CuZn36Pb3 | C3601, C3602 | 57.0-61.0 | – | – | 0.30 | 0.05 | – | Balance | 1.80-3.70 | Sn/0.20, Al/0.30 | – | Leaded/free machining brass is strong, resistant to corrosion, can be both hot-cold formed, good machinability suitable for CNC lathe works |  |

| C38500 | CW614N, CZ121Pb3 | CuZn39Pb3 | C3603, C3604 | 57.0-59.0 | – | – | 0.30 | 0.30 | – | Balance | 2.50-3.50 | Sn/0.30, Al/0.05 | – | Architectural/free machining bronze, excellent machinability, widely used in mass production such as locks, hinges, joints |  |

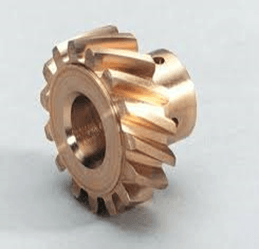

| C83600 | LG2, CuSn5ZnPb5 | CuSn5ZnPb | BC6C, CAC406C | 83.0-87.0 | – | – | 0.30 | 1.00 | – | 4.00-6.00 | 4.00-6.00 | Sn/4.00-6.00, Sb/0.20, | – | Cast leaded gunmetal “tiger bronze”, tough, high pressure-wear resistant, commonly used for making spare parts, pumps, valves |  |

| C90700 | PB1 | CuSn10 | PBC2, CAC502 | Balance | – | – | – | 0.10 | – | 0.10 | 0.25 | Sn/10.0-12.0, | – | Cast phosphorous bronze is strong, resistant to impact-fatigue-corrosion of sea water-brackish water suitable for heavy duty applications as pumps, valves |  |

| C90810 | PB2 | CuSn12 | – | – | – | – | 0.50 | – | 0.30 | Sn/11.2-13.0, | ||||||

| C95400 | AB1 | CuAl10Fe | ALBC2, CAC702 | 80.0-88.0 | – | – | 2.50-5.00 | 1.00-3.00 | <1.50 | – | – | Al/8.00-12.0 | – | Cast aluminum “golden color bronze” has a mixture of Al 5-12%, good toughness, resistant to abrasion-impact-corrosion-heavy use at high temperatures |  |